Radial Engine

Radial engine:-

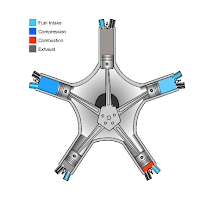

The radial

engine is an internal combustion engine configuration in which the cylinders

point outward from a central crankshaft like the spokes on a wheel. This configuration was

very commonly used in aircraft engines before being superseded by turbo-shaft

and turbojet engines. It is a reciprocating engine.

Although

not that used nowadays radial engine is a cute little engine that was in the

beginning of the aerospace transportation. It was very helpful and mainly used

because of its small weight and size. That makes it comfortable and suitable

for any machine that is close of space. Despite of its small size and weight it

does not make it less powerful than other engines.

The same way the in-line engines are more powerful

with more cylinders it is or powerful with more rows of cylinders. It was also

comfortable for the World War II airplanes when the engine was in its peak.

When it is war you need more space for fuel, power, weapons and bullets than

any other things and than any other time.Engine Assembly:-

The cylinders are connected

to the crankshaft with a master and articulating rod assembly. One cylinder has

a master rod with a direct attachment to the crankshaft. The remaining

cylinders pin their connecting rods attachments to rings around the edge of the

master rod (see animation). Four-stroke radials almost always have an odd

number of cylinders, so that a consistent every other piston firing order can

be maintained, providing smooth operation.

Engine Mechanism Process:-

This

is achieved by the engine taking two revolutions of the crankshaft to complete

the four strokes.

Which means the firing order for a 9-cylinder radial

engine is 1,3,5,7,9,2,4,6,8 and then again back to cylinder number 1. This

means that there is always a two-piston

gap between the piston on its power stroke and the next piston on fire (the

piston on compression).

If

an even number of cylinders was used the firing order would be something

similar to 1,3,5,7,9,2,4,6,8,10 which leaves a three-piston gap between firing

pistons on the first crank shaft revolution, and only one piston gap on the

second crankshaft revolution. This leads to an uneven firing order within the

engine, and is not ideal.

Most radial engines use overhead poppet valves driven

by push rods and lifters on a cam plate which is concentric with the crankshaft,

with a few smaller radials. A few engines utilize sleeve valves instead.

Thanks to share this useful information sir.

ReplyDeletePlease keep it up

Most welcome asad bro!

DeleteZain sab;

ReplyDeleteV inserting topic,Thanx for sare it.

Zain sab;

ReplyDeleteV inserting topic,Thanx for sare it.